Modern defense systems rely heavily on sophisticated electronic countermeasures to maintain operational superiority in increasingly complex threat environments. A jammer module serves as a critical component in these defense architectures, providing targeted signal disruption capabilities that can neutralize hostile communications, navigation systems, and remote-controlled devices. Understanding how these specialized modules integrate into larger defense platforms requires examining their technical specifications, mounting requirements, power distribution needs, and communication protocols with host systems.

The integration process begins with careful consideration of the operational requirements and environmental constraints that will govern the jammer module deployment. Defense equipment designers must evaluate factors such as available space, power budgets, thermal management capabilities, and electromagnetic compatibility requirements before selecting appropriate jamming solutions. These considerations directly impact the selection of specific module configurations and determine the complexity of the integration process.

Successfully implementing a jammer module within defense equipment requires coordination between multiple engineering disciplines, including RF design, mechanical engineering, software development, and systems integration. Each discipline contributes essential expertise to ensure the module operates effectively while maintaining compatibility with existing defense systems and meeting stringent military specifications for reliability and performance.

The physical integration of a jammer module into defense equipment begins with establishing proper mechanical mounting that can withstand operational stresses while providing optimal RF performance. Military-grade mounting systems must accommodate vibration, shock, temperature extremes, and other environmental factors commonly encountered in defense applications. Standard mounting interfaces often include MIL-STD-810 compliant brackets, shock mounts, and thermal interface materials that facilitate heat transfer to the host platform.

Proper positioning of the jammer module within the host equipment affects both RF effectiveness and system maintenance accessibility. Engineers typically design mounting solutions that allow for field replacement while maintaining RF shielding integrity and avoiding interference with other electronic systems. The mounting hardware must also provide adequate clearance for cooling airflow and access to diagnostic connections without compromising the module's electromagnetic shielding properties.

Vibration isolation becomes particularly critical when integrating a jammer module into mobile defense platforms such as vehicles, aircraft, or naval vessels. Specialized mounting systems incorporate elastomeric isolators, tuned mass dampers, or active vibration control mechanisms to protect sensitive RF components from mechanical stress that could degrade performance or reduce operational lifespan.

Effective thermal management represents a fundamental requirement for successful jammer module integration, as these high-power RF devices generate significant heat during operation. The integration design must provide adequate heat dissipation pathways that transfer thermal energy from the module to the host platform's cooling system without creating hot spots or thermal gradients that could affect performance.

Thermal interface materials play a crucial role in establishing efficient heat transfer between the jammer module and host equipment cooling systems. These materials must maintain their thermal conductivity properties across wide temperature ranges while providing electrical isolation when required. Common solutions include thermal pads, phase-change materials, and liquid cooling interfaces that adapt to different integration scenarios.

Advanced defense systems may incorporate active thermal management solutions that monitor jammer module temperatures and adjust cooling parameters dynamically. These systems can optimize cooling efficiency while minimizing power consumption and acoustic signatures that might compromise operational security. Integration with host platform thermal management systems allows for coordinated cooling strategies that consider the entire system's thermal budget.

A jammer module typically requires carefully regulated power supplies that can deliver high instantaneous currents while maintaining voltage stability across varying load conditions. Integration engineers must design power distribution systems that provide clean, stable power while incorporating appropriate filtering, protection, and monitoring capabilities. The power supply design must also accommodate the module's startup sequences and operational power profiles.

Power conditioning becomes essential when integrating jammer modules into defense equipment, as these systems often operate in electrically noisy environments with multiple high-power devices sharing common power buses. EMI filters, isolation transformers, and power factor correction circuits help ensure the jammer module receives clean power while preventing conducted emissions from affecting other systems.

Backup power considerations often influence the integration design, particularly for critical defense applications where uninterrupted operation is essential. Battery backup systems, uninterruptible power supplies, and redundant power sources may be incorporated to ensure the jammer module maintains operational capability during primary power interruptions or battle damage scenarios.

The power distribution architecture for jammer module integration must balance efficiency, reliability, and electromagnetic compatibility requirements. Designers typically implement hierarchical power distribution schemes that provide multiple voltage levels while incorporating appropriate isolation, protection, and monitoring at each level. This approach allows for optimized power delivery while maintaining system-level fault isolation capabilities.

Power sequencing becomes critical during jammer module startup and shutdown procedures to prevent damage to sensitive RF components and ensure proper initialization of control systems. Integrated power management controllers coordinate the activation sequence of different subsystems within the module while monitoring current consumption and fault conditions throughout the process.

Ground isolation and power delivery schemes must consider the high-frequency nature of jammer module operation and the potential for ground loops or common-mode currents that could degrade performance. Careful attention to grounding strategies, including single-point grounds, star configurations, and RF ground planes, helps maintain signal integrity while preventing unwanted coupling between the module and host systems.

Modern jammer module integration relies heavily on digital communication interfaces that enable real-time control, monitoring, and coordination with host defense systems. Common interface standards include Ethernet, RS-485, CAN bus, and MIL-STD-1553, each offering different advantages depending on the specific application requirements and existing system architecture. The selection of communication interfaces affects both integration complexity and operational capabilities.

Protocol implementation for jammer module control systems must accommodate both standard military communication protocols and custom interfaces developed for specific defense applications. These protocols typically include commands for frequency selection, power level control, operational mode selection, and status reporting. The communication system design must also incorporate appropriate error detection, correction, and retry mechanisms to ensure reliable operation in hostile electromagnetic environments.

Real-time communication requirements often drive the selection of communication interfaces and protocol designs for jammer module integration. Time-critical operations such as threat response, coordinated jamming patterns, and emergency shutdown procedures require low-latency communication paths that can deliver commands and receive status updates within strict timing constraints.

Software integration represents a complex aspect of jammer module implementation, requiring coordination between module-specific control software and host system applications. The software architecture must provide standardized interfaces that allow the jammer module to integrate seamlessly with existing defense system software while maintaining modularity and upgrade capability. This often involves developing custom device drivers, application programming interfaces, and integration middleware.

Configuration management systems enable defense operators to customize jammer module parameters for specific mission requirements while maintaining version control and audit trails. These systems typically include database-driven configuration tools, mission planning interfaces, and automated deployment capabilities that simplify the process of adapting the module's operational parameters to changing tactical requirements.

Diagnostic and maintenance software integration allows host defense systems to monitor jammer module health, predict maintenance requirements, and troubleshoot operational issues. Built-in test equipment interfaces, performance monitoring algorithms, and fault isolation procedures help maintain high availability while minimizing maintenance downtime and logistics burden.

Proper antenna integration represents a critical success factor for jammer module effectiveness, as the antenna system directly affects the module's ability to deliver RF energy to target frequencies and coverage areas. Impedance matching between the jammer module output and antenna input must be optimized across the entire operational frequency range to maximize power transfer efficiency and minimize reflected power that could damage the module's output stages.

Antenna selection for jammer module integration depends on factors including operational frequency bands, required coverage patterns, physical constraints, and stealth considerations. Common antenna types include broadband horns, log-periodic arrays, phased arrays, and specialized directional antennas designed for specific jamming applications. The integration design must accommodate the selected antenna's mechanical, electrical, and environmental requirements.

Transmission line design between the jammer module and antenna system affects both RF performance and integration complexity. Low-loss coaxial cables, waveguides, or integrated transmission line structures must be selected based on frequency range, power levels, and physical routing constraints. Proper transmission line design minimizes insertion loss while maintaining impedance control and preventing unwanted radiation or pickup.

Advanced jammer module installations often incorporate multiple antenna systems to provide comprehensive coverage, directional control, or redundancy capabilities. These multi-antenna configurations require sophisticated RF switching systems, power dividers, and control logic that coordinate the activation of different antenna elements based on operational requirements and threat analysis.

Antenna isolation becomes critical in multi-antenna jammer module installations to prevent mutual coupling that could degrade performance or create unwanted interference patterns. Physical separation, absorptive materials, and frequency-selective filters help maintain isolation between antenna elements while preserving the overall system's jamming effectiveness.

Beam steering and null steering capabilities in advanced antenna systems allow the jammer module to focus energy toward specific targets while minimizing interference to friendly communications. These capabilities require sophisticated RF control systems and real-time processing capabilities that integrate with the host defense system's threat detection and analysis functions.

Electromagnetic compatibility considerations are paramount when integrating a jammer module into complex defense equipment, as these high-power RF devices can generate significant electromagnetic emissions that may interfere with sensitive electronic systems. EMC design must address both conducted and radiated emissions while ensuring the module maintains immunity to external electromagnetic interference that could degrade its operational performance.

Shielding design for jammer module integration typically involves multiple layers of protection, including RF gaskets, conductive enclosures, and filtered connections that prevent unwanted electromagnetic energy from entering or leaving the module compartment. The shielding effectiveness must be maintained across the entire operational frequency range while accommodating necessary openings for cooling, control connections, and antenna interfaces.

Grounding and bonding strategies play crucial roles in maintaining electromagnetic compatibility during jammer module integration. Proper grounding techniques help establish reference potentials, minimize ground loops, and provide low-impedance paths for RF currents. Bonding between different metal structures ensures electrical continuity and prevents the formation of slot antennas or other unintentional radiating elements.

Environmental protection requirements for jammer module integration often include resistance to moisture, dust, salt spray, temperature extremes, and chemical exposure depending on the intended deployment environment. Sealing solutions must protect internal components while maintaining electromagnetic shielding effectiveness and allowing for necessary thermal management and electrical connections.

IP ratings and MIL-STD environmental specifications typically govern the selection of sealing technologies and materials used in jammer module integration. Gaskets, seals, and protective coatings must maintain their properties across wide temperature ranges while providing long-term reliability in harsh operational environments. The sealing system design must also accommodate maintenance access requirements without compromising protection levels.

Pressure equalization systems may be necessary for jammer module installations that experience significant altitude or temperature changes during operation. Breathable membranes, pressure relief valves, and desiccant systems help maintain internal environmental conditions while preventing moisture accumulation that could cause corrosion or electrical failures.

Comprehensive testing procedures are essential for validating proper jammer module integration and ensuring operational effectiveness within the host defense system. Performance testing typically includes RF output power measurements, frequency accuracy verification, spurious emission analysis, and jamming effectiveness evaluation across the intended operational spectrum. These tests must be conducted using calibrated instrumentation and standardized test procedures that provide repeatable results.

Integration testing extends beyond individual jammer module performance to evaluate system-level functionality, including communication interfaces, control system integration, and coordination with other defense subsystems. This testing phase often reveals integration issues that may not be apparent during individual component testing and requires comprehensive test scenarios that simulate realistic operational conditions.

Environmental testing validates the integrated jammer module's performance under conditions that simulate actual deployment environments. Temperature cycling, vibration testing, humidity exposure, and electromagnetic compatibility testing help ensure the integrated system maintains specifications throughout its operational lifetime and under adverse conditions.

Formal acceptance testing procedures provide final validation that the integrated jammer module meets all specified requirements and is ready for operational deployment. These tests typically follow predetermined test plans that verify compliance with performance specifications, environmental requirements, electromagnetic compatibility standards, and operational procedures.

Documentation and certification processes accompanying acceptance testing provide traceability and compliance verification for military standards and regulatory requirements. Test reports, configuration records, and certification documents establish baseline performance data and provide reference information for future maintenance and modification activities.

Operational readiness testing demonstrates that integrated jammer module systems can perform their intended missions effectively while operating alongside other defense equipment. This testing phase often involves realistic scenario simulation and may include coordination with other military units or systems to validate interoperability and effectiveness in representative operational environments.

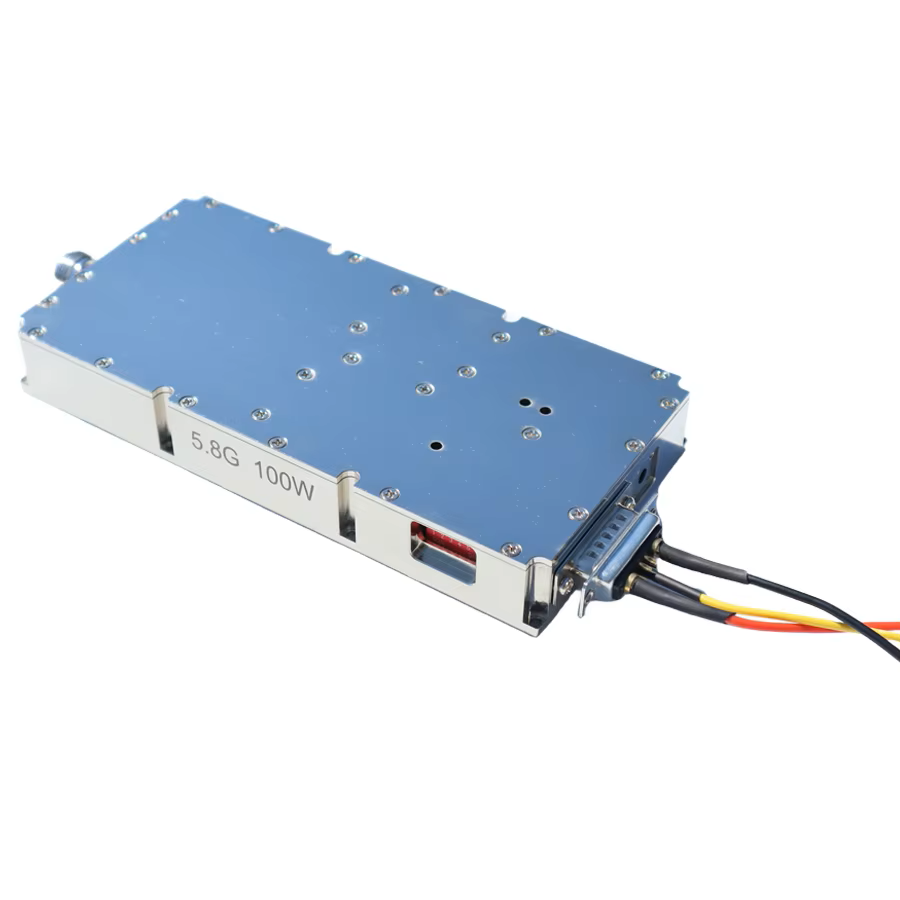

Defense-grade jammer modules typically require high-current, regulated power supplies capable of delivering 100 watts to several kilowatts of RF output power. The exact power requirements depend on the operational frequency range, coverage area, and jamming effectiveness specifications. Most military jammer modules operate from 28V DC vehicle power or 115V/400Hz aircraft power systems, requiring sophisticated power conditioning and distribution systems to provide clean, stable power while meeting electromagnetic compatibility requirements.

Environmental factors significantly influence jammer module integration design, particularly temperature extremes, humidity, vibration, and electromagnetic interference. The integration design must incorporate appropriate thermal management systems, environmental sealing, shock mounting, and electromagnetic shielding to ensure reliable operation across military operating temperature ranges typically from -40°C to +71°C. Salt spray resistance, fungus resistance, and altitude compensation may also be required depending on the deployment environment.

Common communication interfaces for jammer module control include Ethernet for high-bandwidth applications, RS-485 for multi-drop serial communication, CAN bus for vehicle integration, and MIL-STD-1553 for military aircraft applications. The selection depends on the host system architecture, data rate requirements, environmental constraints, and existing communication infrastructure. Modern jammer modules often support multiple interface types to provide flexibility during integration into different defense platforms.

Typical jammer module integration into defense equipment ranges from several months for straightforward installations to over a year for complex, multi-platform integrations requiring extensive customization. The timeline depends on factors including system complexity, environmental requirements, testing procedures, certification requirements, and the need for custom mechanical, electrical, or software interfaces. Integration projects involving new antenna systems, power distribution modifications, or extensive software development typically require longer development periods and more comprehensive testing phases.